Phone

+86.18662690468

ylwoverseas@gmail.com

ylwoverseas@gmail.com

Category:All Spiral Mesh Belt

Category:All Spiral Mesh Belt

Material:

Material:

Application:

Application:

Visits:5848

Visits:5848

Email:

Email:

ylwoverseas@gmail.com

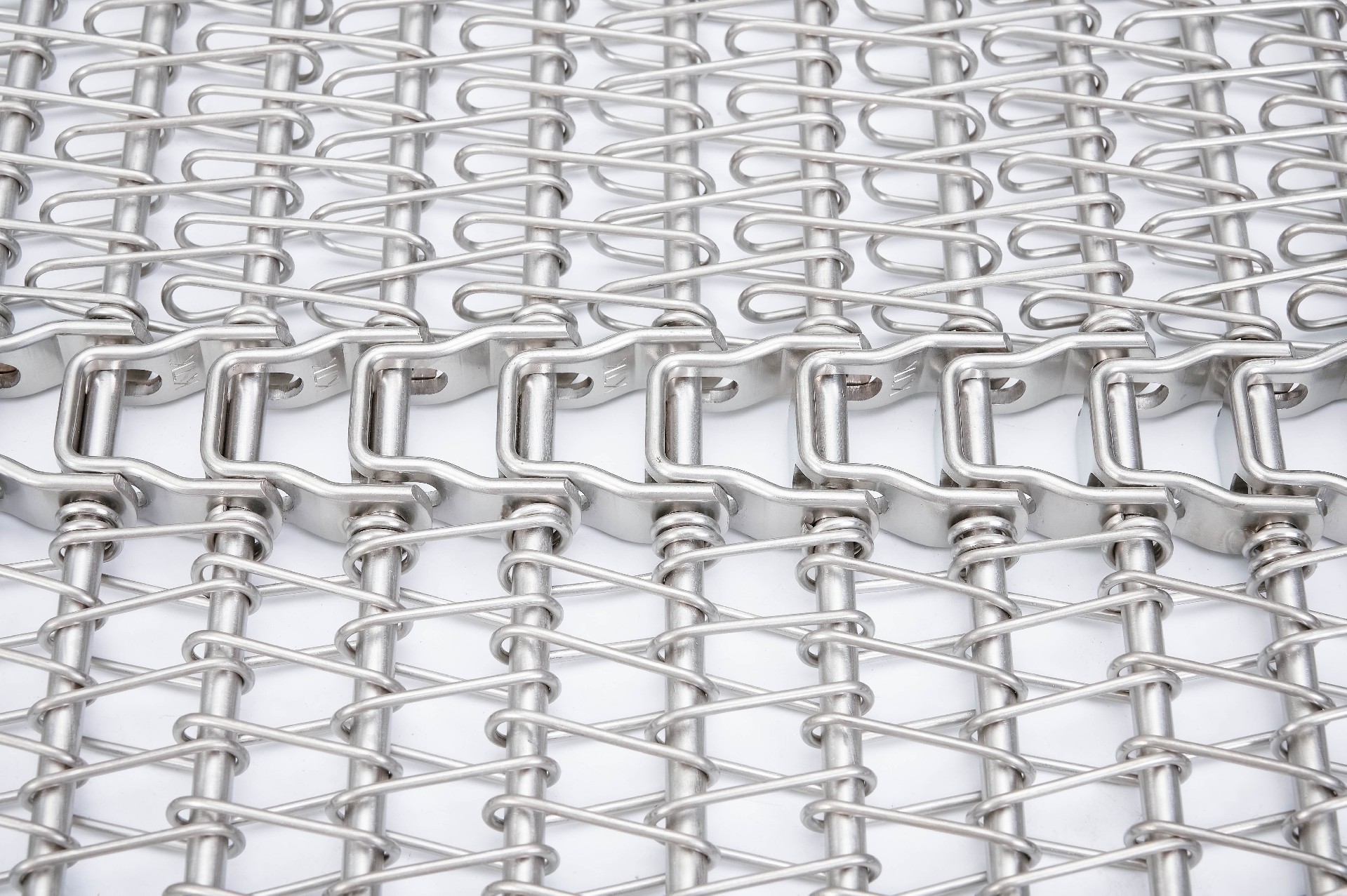

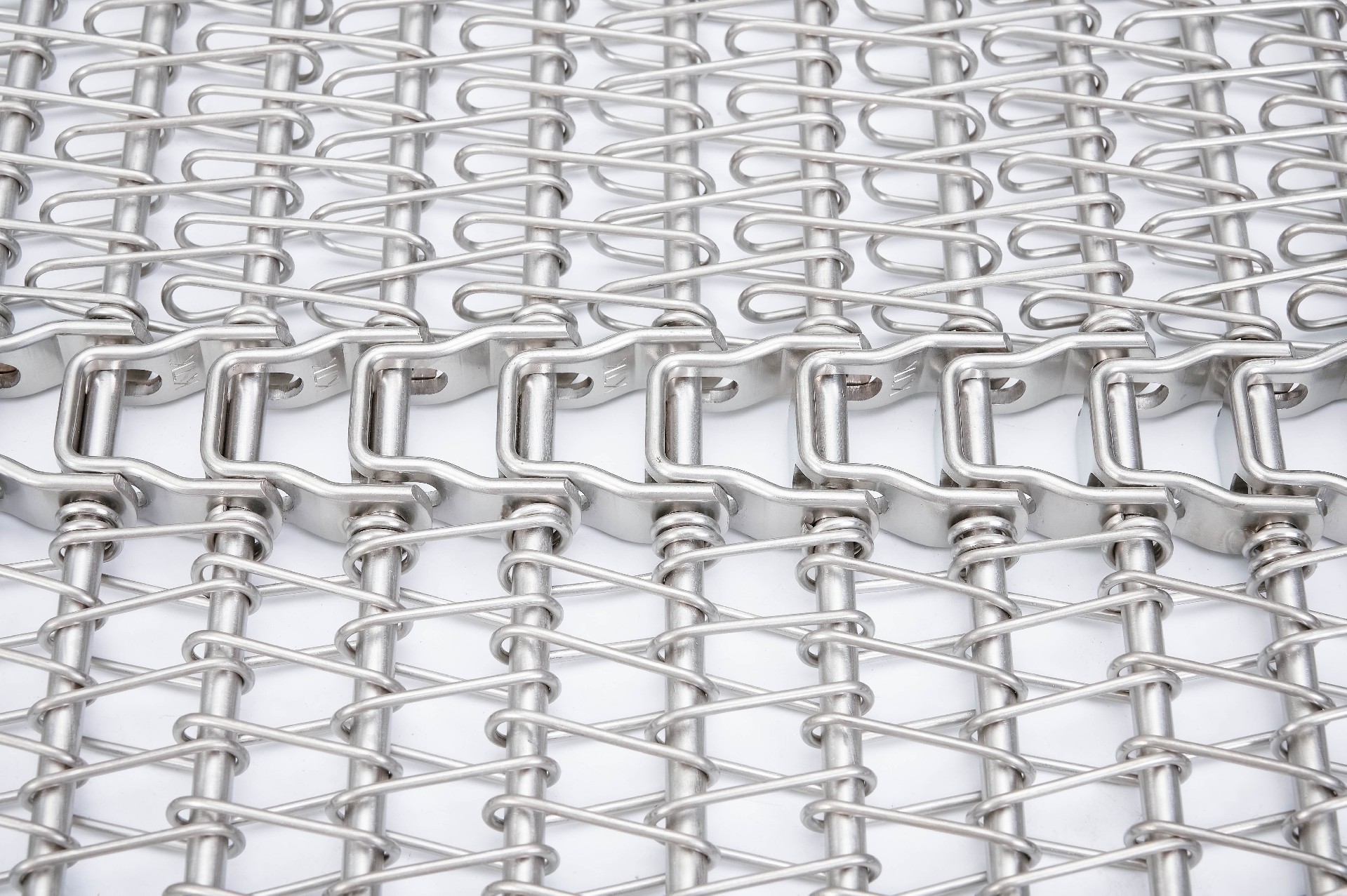

In the field of food processing and freezing, the demand for conveying equipment that can adapt to low-temperature environments, meet strict hygiene standards, and navigate tight-turn layouts in freezing tunnels has become increasingly stringent. Among various conveying components, the spiral mesh belt for small radius 3 rows link emerges as a specialized and high-performance solution, tailored to address the unique challenges of confined and low-temperature conveying scenarios in food freezing processes.

The core design of this spiral mesh belt centers on its 3 rows link structure, which significantly enhances both stability and flexibility—two critical attributes for food freezing applications. In freezing tunnels, where space is often limited and tight radii turns are inevitable, standard mesh belts tend to suffer from issues like jamming, uneven tension distribution, or material (food) slippage, which can compromise production efficiency and food safety. By contrast, the 3 rows link configuration of this spiral mesh belt evenly distributes tension across the entire belt surface, enabling it to bend smoothly around small radii without deformation. This ensures consistent contact between the belt and the conveying path, preventing frozen food products from shifting or falling off during transport. Whether conveying delicate bakery items, meat products, or fruits and vegetables in spiral freezers or straight-line freezing tunnels, this design feature guarantees reliable and efficient material handling while safeguarding the integrity of food products.

For food processing and freezing applications, the spiral mesh belt for small radius 3 rows link is predominantly constructed from food-grade 304 or 316 stainless steel.

Another key advantage of this spiral mesh belt lies in its customizable versatility and standardized model parameters, which are particularly optimized for IQF freezing systems. Typical model specifications include: Model SM-SR-3R (Spiral Mesh - Small Radius - 3 Rows), with wire diameter options of 1.2mm, 1.5mm, and 2.0mm (all food-grade 304/316 stainless steel complying with ASTM A240 standard); pitch sizes of 8mm, 10mm, and 12mm to match different IQF conveyor speed requirements; minimum bending radius of 300mm, enabling seamless adaptation to the compact layout of IQF freezing tunnels; belt width ranging from 500mm to 2000mm (customizable up to 5500mm for large-scale IQF lines) and mesh aperture options of 2mm×2mm to 10mm×10mm . For IQF systems handling small, fragile items like berries, peas, or diced vegetables, the SM-SR-3R-1.2/8/2 model (1.2mm wire, 8mm pitch, 2mm aperture) is recommended to prevent product leakage while ensuring maximum air circulation. For larger IQF products such as shrimp or chicken nuggets, the SM-SR-3R-2.0/12/10 model offers enhanced load-bearing capacity (tensile strength ≥550MPa) without compromising permeability. Additionally, specialized surface treatments like electrolytic polishing (achieving surface roughness Ra≤0.8μm) or passivation can be applied to further improve hygiene and anti-corrosion performance, meeting global food safety standards including FDA, EU 10/2011, and Japan JIS A8401 . This combination of standardized parameters and customization capability allows the belt to seamlessly integrate into various IQF freezing equipment, adapting to the diverse processing needs of frozen food enterprises.

The excellent air permeability and 3-row link structure of the spiral mesh belt for small radius 3 rows link make it a perfect match for IQF freezing systems, where individual quick freezing of products is critical. IQF systems rely on high-velocity cold air (typically -30℃ to -40℃) to rapidly freeze each food particle independently, and the open spiral mesh structure of the belt ensures unobstructed circulation of this cold air—allowing it to pass freely through the belt and around every individual food item, eliminating air pockets and ensuring consistent heat transfer . Compared to solid conveying belts or traditional single-row mesh belts, this design reduces freezing time by 20-30%, significantly improving production throughput while preserving the nutritional value, texture, and taste of frozen products. The 3-row link structure further enhances the belt's stability during high-speed operation (common in IQF systems with conveyor speeds up to 0.5-2m/s), preventing belt deviation (anti-snake deviation ≤2mm/m) and ensuring uniform product distribution on the belt surface . This uniform distribution avoids product clumping—a major pain point in IQF processing—ensuring each item is fully exposed to cold air for consistent freezing. Moreover, the belt's food-grade stainless steel construction resists corrosion from IQF freezing agents (such as liquid nitrogen or carbon dioxide) and prevents food adhesion, while the permeable structure facilitates rapid drainage of condensation and defrost water in IQF tunnels. This reduces the risk of ice buildup on the belt surface, avoiding potential slippage hazards and ensuring continuous, stable operation of the IQF system. The belt's easy-to-clean design also aligns with the frequent sanitation requirements of IQF facilities, allowing for quick disassembly and cleaning to meet strict food hygiene regulations .

Overall, the spiral mesh belt for small radius 3 rows link (Model SM-SR-3R) is a meticulously engineered solution specifically optimized for IQF freezing systems in the food processing industry. By combining precise model parameters, superior low-temperature resistance (stable operation at -40℃), strict hygiene compliance, flexible small-radius navigation, and efficient IQF-specific freezing performance, it addresses the core pain points of IQF conveying systems—such as product clumping, uneven freezing, space constraints, and hygiene compliance. For food processing enterprises seeking to enhance the efficiency and quality of their IQF operations, ensure food safety, and optimize space utilization in freezing facilities, this specialized spiral mesh belt is an indispensable and reliable choice. It has been successfully applied in IQF lines for fruits, vegetables, seafood, and poultry, proving its value in delivering consistent, high-quality frozen products while reducing maintenance costs and downtime .

Knowledge

Knowledge