Phone

+86.18662690468

ylwoverseas@gmail.com

ylwoverseas@gmail.com

Category:balanced weave mesh belt

Category:balanced weave mesh belt

Material:

Material:

Application:

Application:

Visits:5884

Visits:5884

Email:

Email:

ylwoverseas@gmail.com

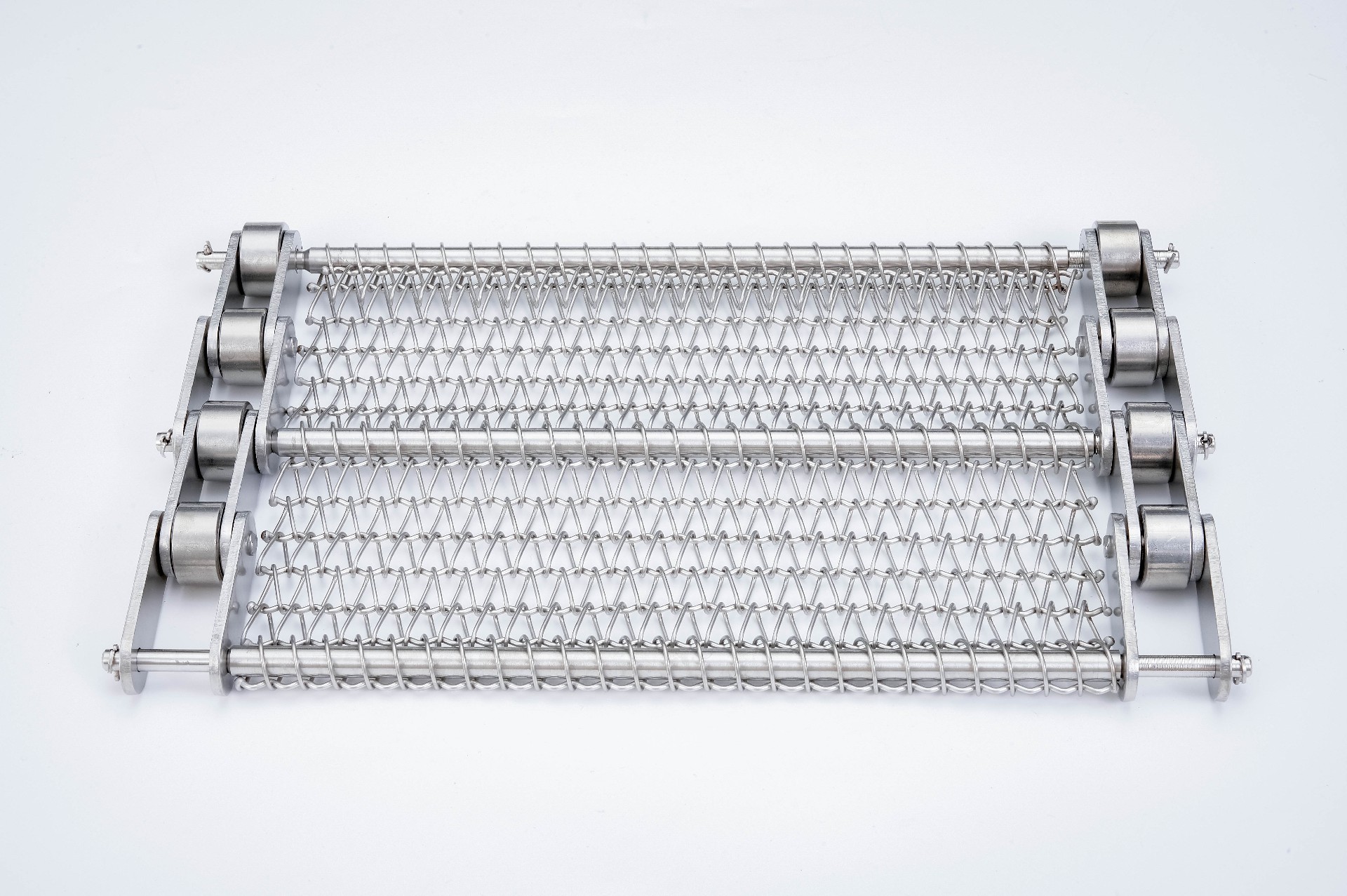

The balanced weave mesh belt with chain stands out as a high-performance variant of metal conveyor meshes, engineered to combine the flexibility of balanced weave construction with the robust tension-bearing capacity of chain drives. Designed for demanding industrial conveying applications, this belt type delivers exceptional stability, uniform load distribution, and long service life, making it a preferred choice across diverse manufacturing and processing sectors.

At the core of its design, the balanced weave structure features interlocking metal wires arranged in a symmetrical pattern, ensuring consistent mesh openings that facilitate efficient airflow, heat transfer, and drainage. This design not only minimizes material accumulation but also allows for gentle handling of products, reducing the risk of damage during conveyance. The integrated chain drive system—typically mounted on both sides of the mesh—provides precise power transmission, preventing slippage even under heavy loads or high-speed operation. This synergy of balanced weave and chain drive results in a conveyor belt that maintains steady movement, even when transporting irregularly shaped or heavy items.

Material selection for the balanced weave mesh belt with chain is strictly application-driven, tailored to withstand the specific environmental and operational conditions of each use case. For standard ambient-temperature applications such as general assembly lines or packaging processes, carbon steel is often the go-to choice, offering an optimal balance of strength and cost-effectiveness. In high-temperature environments—such as heat treatment furnaces, sintering processes, or bakery ovens—high-temperature alloys like 304 or 316 stainless steel are preferred, as they resist oxidation and maintain structural integrity at temperatures up to 1200°F (648°C). For corrosive environments, such as chemical processing plants or food processing facilities requiring frequent cleaning, stainless steel or galvanized steel variants are selected to prevent rust and ensure compliance with hygiene standards.

Knowledge

Knowledge