Phone

+86.18662690468

ylwoverseas@gmail.com

ylwoverseas@gmail.com

Category:compound balanced mesh belt

Category:compound balanced mesh belt

Material:

Material:

Application:

Application:

Visits:58106

Visits:58106

Email:

Email:

ylwoverseas@gmail.com

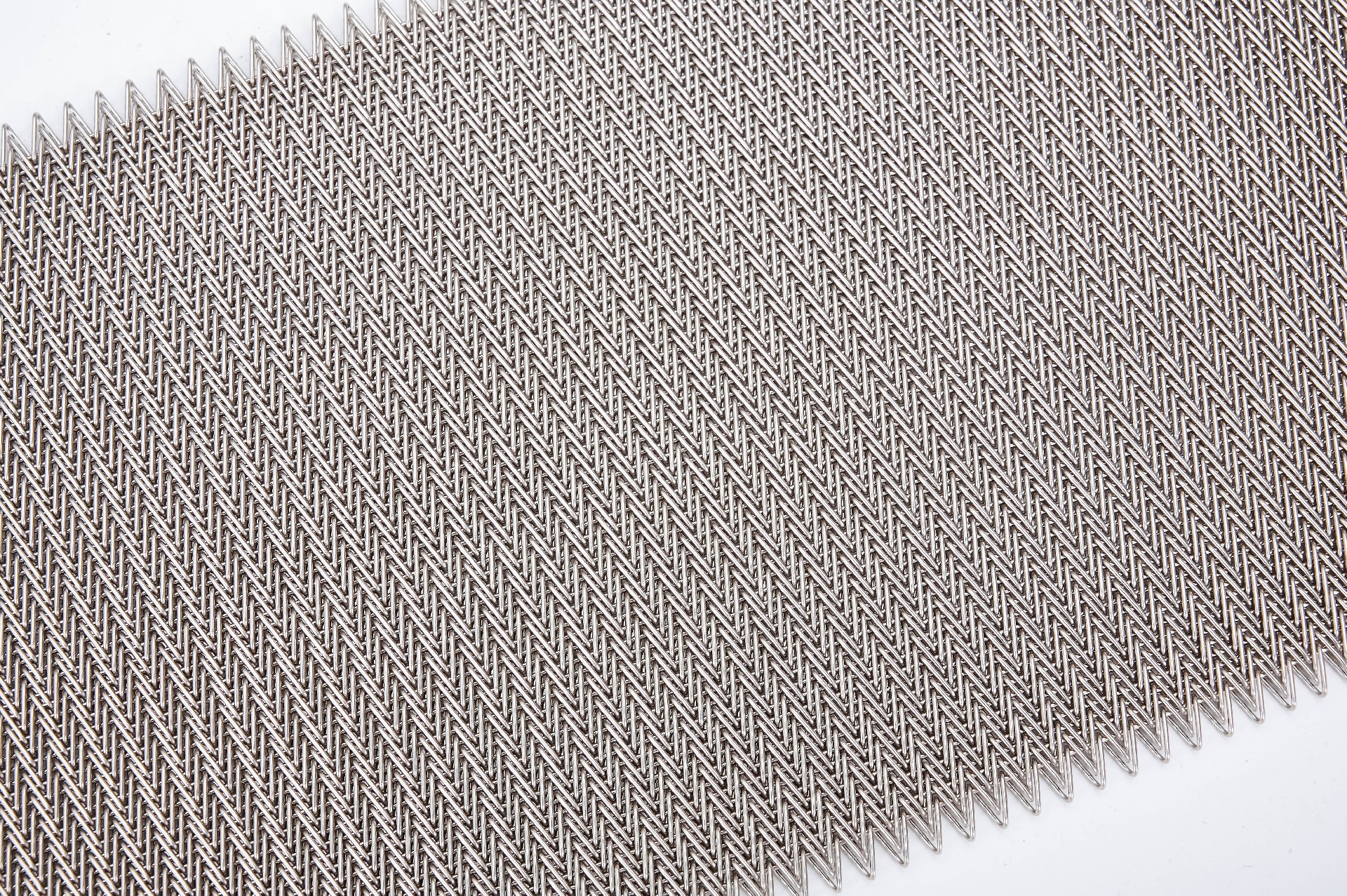

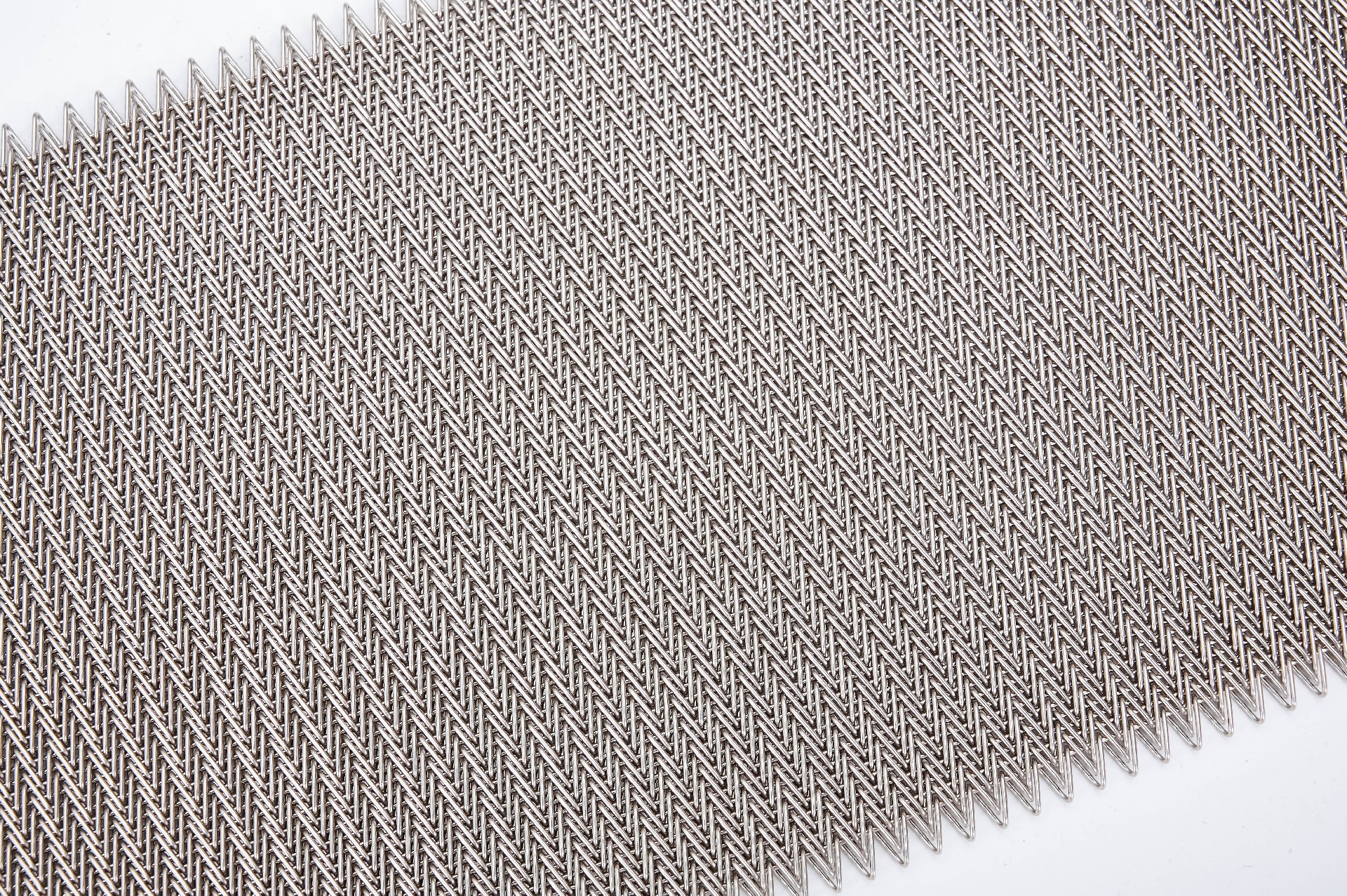

A compound balanced mesh belt, also known as a cordweave or compound weave belt, is a tightly woven conveyor belt designed to carry very small, delicate, or heavy products. Its dense construction of multiple interwoven spirals results in a smooth, flat surface with minimal open area.

The primary advantages of a compound balanced mesh belt are its high density, smooth and flat carrying surface, and durability, which allow for the conveyance of small, delicate, or heavy products in processes involving extreme temperatures.

Advantages

Small, tight mesh: The design features multiple left and right spirals nested together, creating a dense mesh with very small openings. This prevents small, unstable, or top-heavy products from falling through.

Smooth, flat surface: The high-density weave provides a smooth and flat conveying surface, which is ideal for handling delicate items and provides consistent, stable product transport.

Uniform heat transfer: The high-density construction allows for very uniform heat distribution, which is crucial for processes like baking and heat treating.

High tensile strength: The compact, compound structure gives the belt high tensile strength, enabling it to transport heavy loads.

High-temperature resistance: These belts are available in materials like stainless steel and high carbon steel that can withstand extreme hot and cold temperatures, making them suitable for furnaces, ovens, and freezing tunnels.

Durability and low maintenance: The robust construction ensures long service life and resistance to wear and abrasion, which reduces overall maintenance costs and downtime.

Corrosion resistance: When made from stainless steel, the belts offer excellent resistance to rust and corrosion, making them suitable for chemical processing and washdown environments.

Applications

Food Processing and Baking: Widely used for baking crackers, cookies, and other baked goods, as the dense, smooth surface and uniform heat transfer ensure a consistent product. They are also used for freezing, pasteurizing, and drying food products.

Heat Treatment: The high-temperature resistance makes them suitable for metal parts processing, including annealing, hardening, and quenching operations.

Manufacturing: Excellent for conveying very small mechanical parts, fasteners, and components, such as nuts, bolts, and screws, especially in assembly or heat-treating processes.

Glass and Ceramics: Used in processes that require high temperatures, such as glass annealing and drying ceramic items.

Chemical Processing: The corrosion-resistant options are ideal for conveying materials through chemical washes or processes.

Pharmaceuticals: The hygienic and easy-to-clean nature of stainless steel belts makes them well-suited for pharmaceutical manufacturing, where strict cleanliness standards are required.

Knowledge

Knowledge