Phone

+86.18662690468

ylwoverseas@gmail.com

ylwoverseas@gmail.com

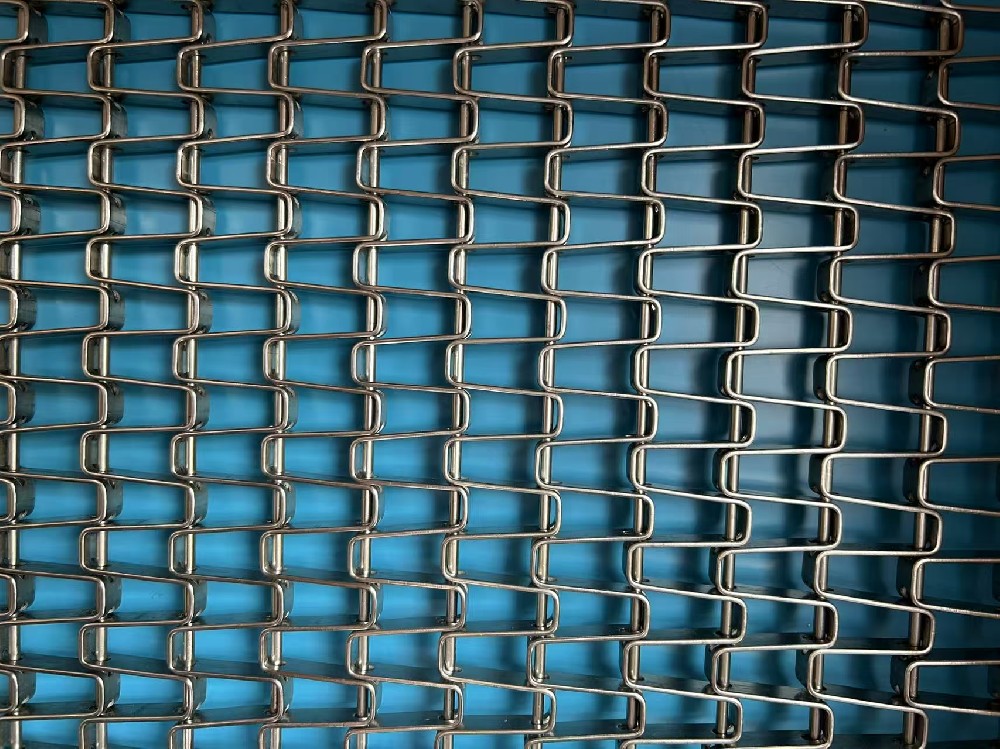

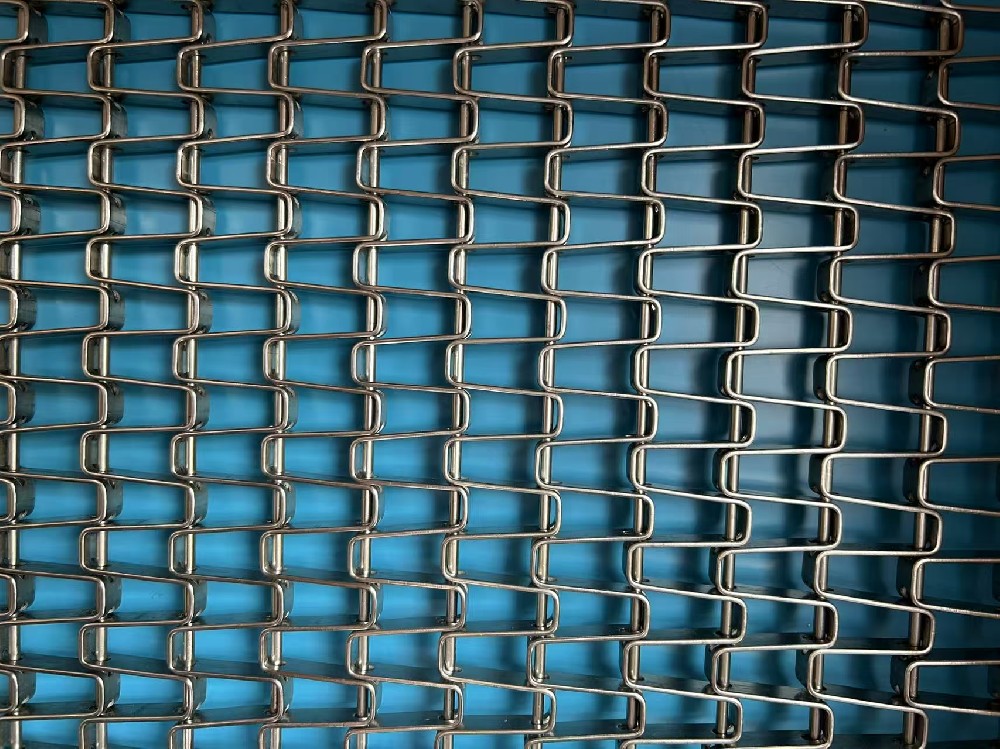

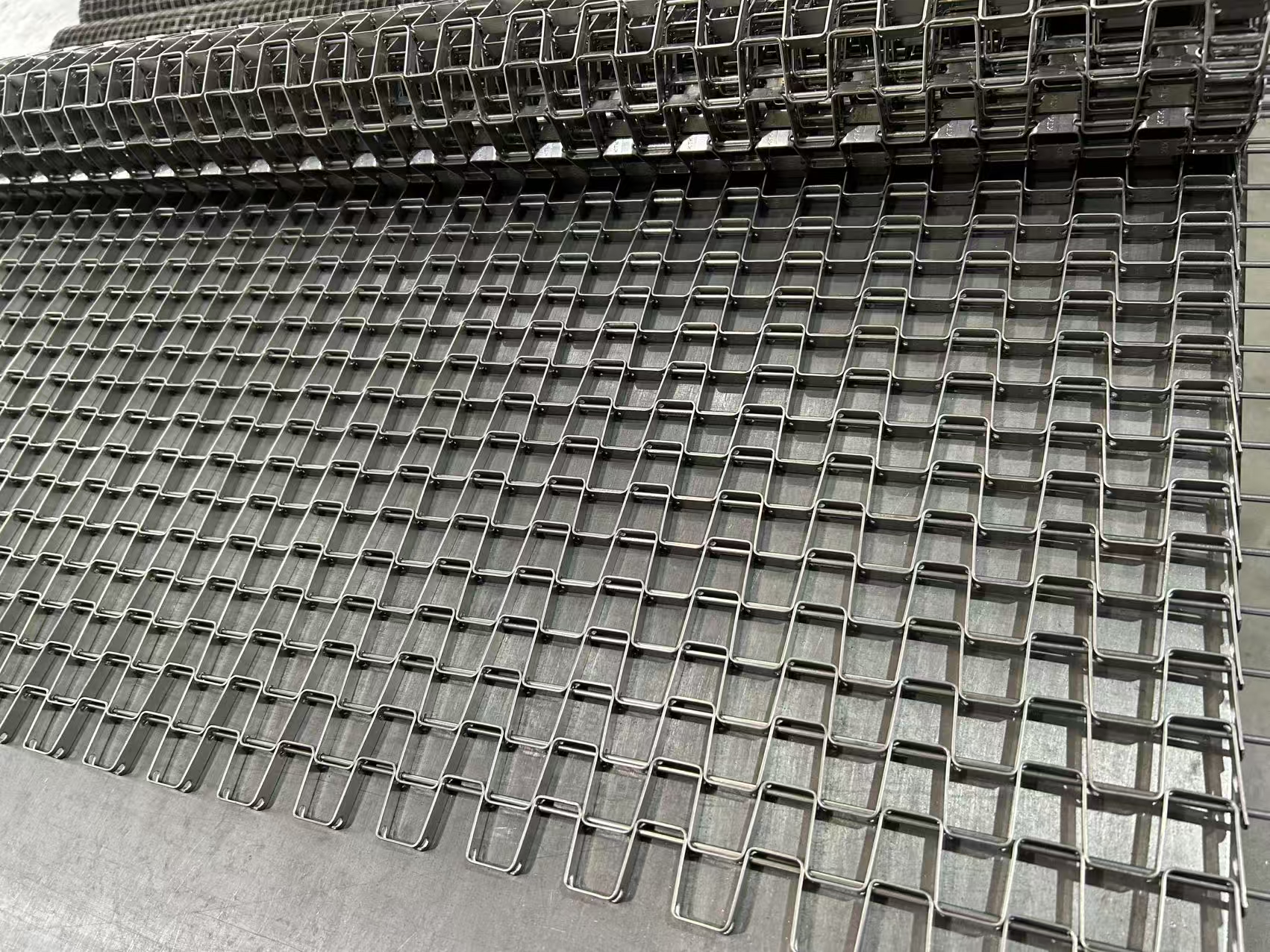

Category:flat wire mesh belt

Category:flat wire mesh belt

Material:

Material:

Application:

Application:

Visits:58137

Visits:58137

Email:

Email:

ylwoverseas@gmail.com

Flat wire mesh belt is a specialized conveyor component in the metal conveyor mesh sector, fabricated by weaving or welding flat metal wires into a continuous, flexible belt structure. It is engineered to facilitate efficient, stable material transportation across diverse industrial processes, distinguishing itself from round-wire counterparts via its enhanced load-bearing surface and structural rigidity.

Knowledge

Knowledge