Phone

+86.18662690468

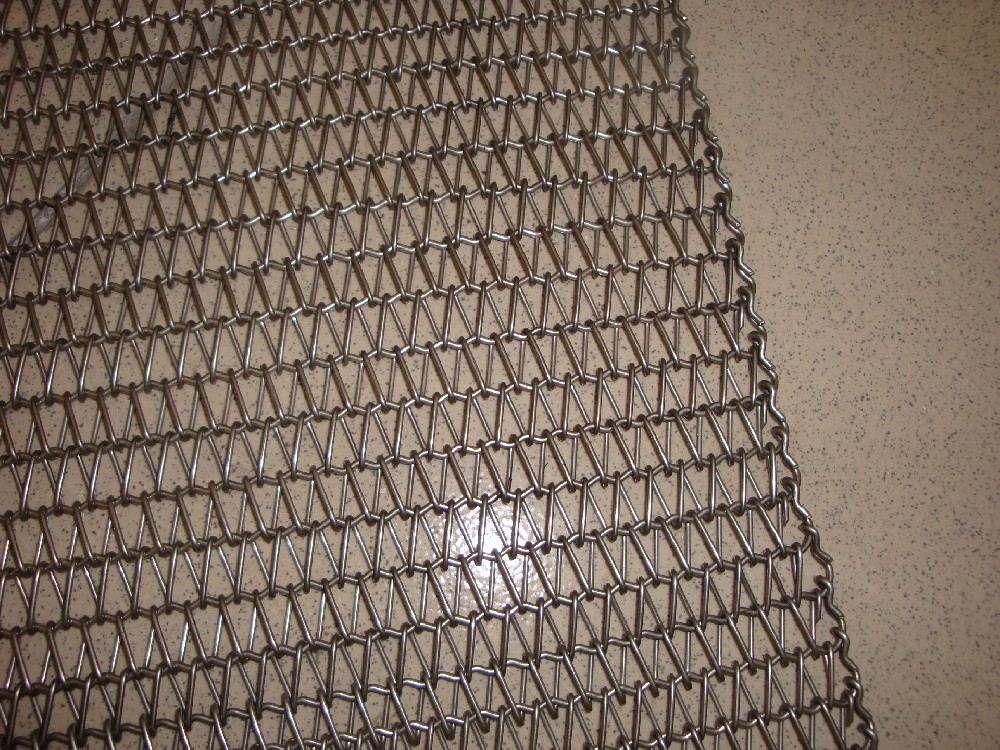

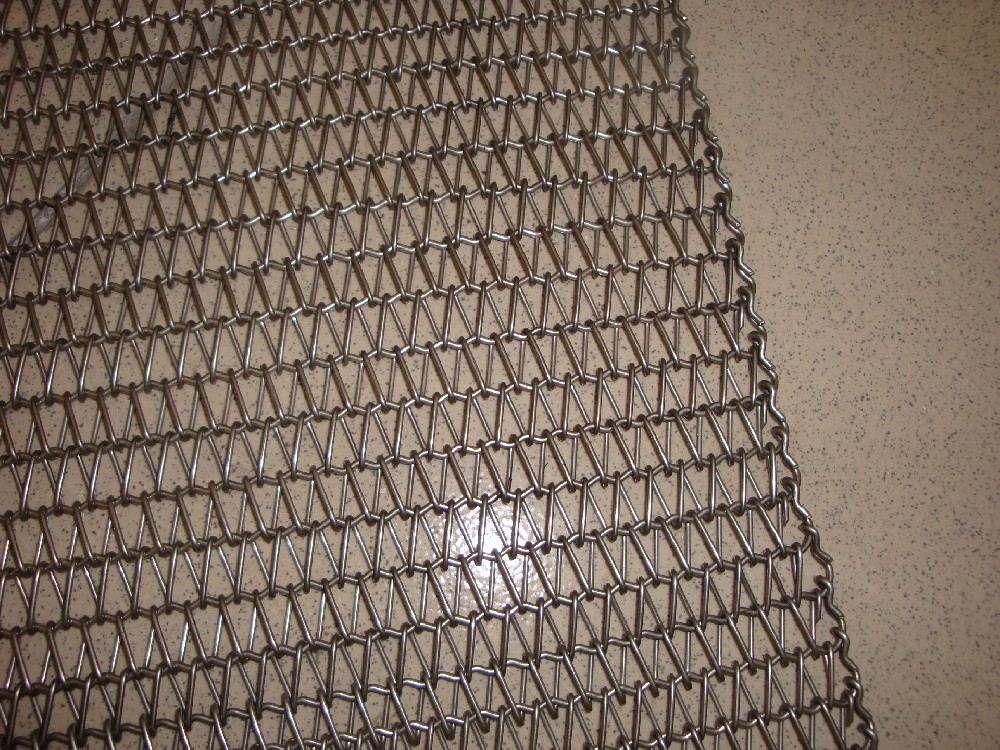

Category:balanced wave mesh belt

Category:balanced wave mesh belt

Material:

Material:

Application:

Application:

Visits:3

Visits:3

Email:

Email:

ylwoverseas@gmail.com

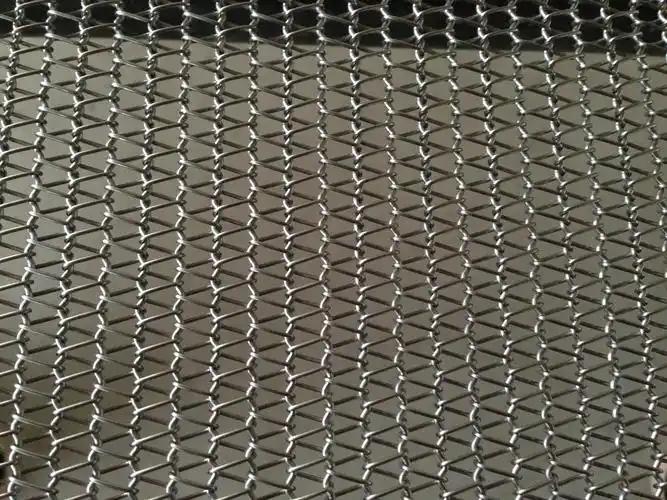

A sprocket-driven balanced weave mesh belt is a versatile conveyor system that uses sprockets to engage the belt's mesh and ensure reliable, positive tracking. A balanced weave belt, the most common type of wire mesh conveyor belt, is made of alternating left and right-hand spirals connected by crimped rods. While many balanced weave belts are friction-driven, a positive, sprocket-driven configuration is used for applications that require precise alignment and have heavier loads.

A balanced wave mesh belt driven by sprockets offers significant advantages in stability, durability, and positive tracking, making it ideal for applications that require precise product placement and can withstand extreme conditions.

Advantages

Positive, slip-free drive: The sprockets engage directly with the belt's mesh, eliminating belt slippage. This ensures consistent speed, precise product timing, and accurate tracking, which is essential for automated processes.

Straight and stable tracking: The balanced spiral construction, combined with the sprocket drive, prevents the belt from veering to one side. This minimizes downtime and wear caused by drift.

High strength and load capacity: With its interlocking spiral design and solid cross rods, this type of belt has an excellent strength-to-weight ratio and can carry heavy loads without stretching or deforming.

Durability and temperature resistance: Built from durable metal materials like stainless steel, the belt can withstand a wide range of extreme temperatures, from cryogenic freezing to the intense heat of industrial furnaces.

Easy to clean and maintain: The open mesh structure allows for easy cleaning, promotes good airflow and drainage, and reduces dirt and debris accumulation. Maintenance is simplified, as individual sections can be replaced if damaged.

Versatility: The mesh size, wire diameter, and material can be customized for specific product sizes and process requirements.

Applications

The unique characteristics of this conveyor system make it suitable for a wide array of industrial applications, particularly in demanding environments.

Food processing: Used in baking ovens, cooling tunnels, freezing lines, and wash-down applications. The open mesh allows for even heat distribution and quick drainage.

Heat treatment and metalworking: Transports metal parts through high-temperature processes such as annealing, tempering, and quenching.

Glass and ceramics: Moves hot glass and ceramic products through cooling and finishing stages.

Drying and cooling: Used in processes that require continuous airflow, such as drying agricultural products or cooling hot parts in manufacturing.

Automotive: Used in processes involving extreme temperatures, such as paint drying ovens or parts quenching lines.

Electronics manufacturing: Conveys circuit boards and other components through assembly and soldering, where precise movement is critical.